Home / All / Alloy Metal Processing / Tungsten Copper Alloys / Wcu25 tungsten copper alloy bar with high temperature resistance used in electric power industry

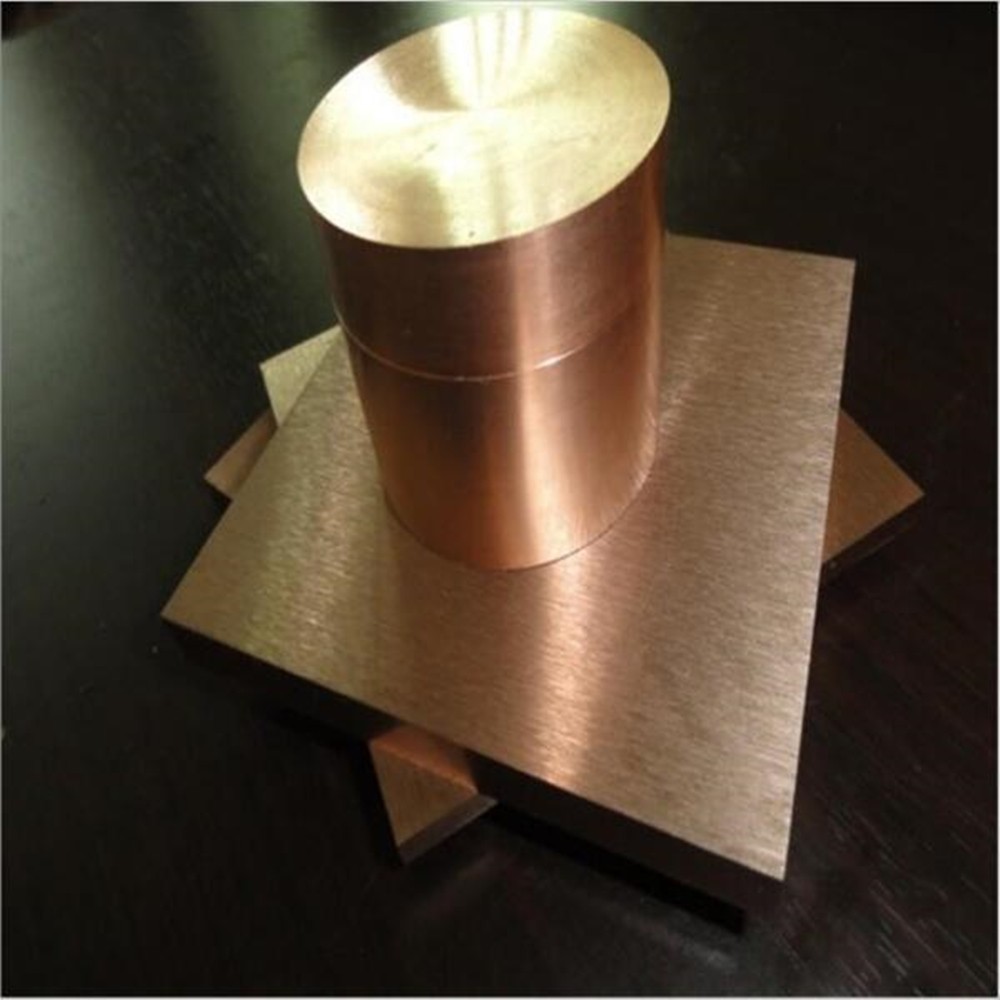

Wcu25 tungsten copper alloy bar with high temperature resistance used in electric power industry

| Share | |

|---|---|

| Categories | Tungsten Copper Alloys |

| Trademark/Brand | MMR Parts Processing | Custom Parts Manufacturing |

| Grade | WCu10,Wcu15,WCu20,WCu25,WCu30 |

| Szie | according to customer requirement |

| Density | 14-17g/cm3 |

| Technology | powder metallurgy method |

| Surface | bright surface, |

| Specifications | Electronics, electric power, metallurgy |

| FOB port | shanghai,Tianjin |

| Terms of Payment | L/C, D/A, D/P, Western Union |

| Update Time | Feb 5,2026 |

Detail Information

AS a copper nickel alloy suppliers, Our tungsten copper alloy mechanical properties is very qualfified and it is also with good chemical composition too. The tunsten copper alloy melting point can reach 3000 degree. becasue of our copper tunsten alloy price is so competitive ,so we have sell to many customers.

Grade and mechanical properties

|

Grade

|

Density

|

conductivity

|

expansion coefficient

|

|

WCu7

|

17.5

|

150

|

5.5

|

|

WCu10

|

17.0

|

160

|

6.2

|

WCu15 | 16.2 | 170 | 6.9 |

Wcu20 | 15.4 | 180 | 7.4 |

Wcu25 | 14.7 | 200 | 8.0 |

Wcu30 | 14.1 | 220 | 8.8 |

Testing :

Chemical composition test,

Physical properties test,

Appearance defects inspection,

tolerance testing.

Military high temperature resistant materials,

Electrical alloys for high voltage switches,

Electro machining electrodes,

Microelectronic materials,

Aerospace,

Electronics, electricity,

Metallurgy, machinery,

Sports equipment and other industries

Features :

Tungsten-copper alloy combines the advantages of copper and tungsten,

High strength, high specific gravity, high temperature resistance,

Arc ablation resistance, good electrical conductivity and heating performance, and good processing performance.

Using high-quality tungsten powder and oxygen-free copper powder, applying isostatic pressing (high temperature sintering-copper infiltration) to ensure product purity and accurate proportioning,

Fine structure and excellent performance,

The arc breaking performance is good, the electrical conductivity is good, the thermal conductivity is good, and the thermal expansion is small.

What we can do for you?

- If the above model is not suitable for your workpiece, please tell us your need and then we can send you the most satisfying drawing.

- contact us

Review

- Loading...

More than 10 year Foundry Operation Experience.

Committed to titanium processing and productionExported to +20 Overseas Countries.

- Mobile Phone

- *Title

- *Content

Titanium Custom Parts Manufacturing

NAVIGATION

More than 10 year Foundry Operation Experience.

Committed to titanium processing and productionExported to +20 Overseas Countries.

- Mobile Phone

- *Title

- *Content

Titanium Custom Parts Manufacturing

INFORMATION

- Tel:

+0086-917-3323952

+0086-15592563725

- WhatsApp:

- 8615592563725

- Skype:

- viresells2

- Address:

- Guojiacun Industry park,Maying Town,Weibin District,Baoji Shaanxi,P.R.China