Home / All / Titanium Processing / Titanium Wires / Titanium Coil Wires / Good heat resistance titanium wire in coil for industry application

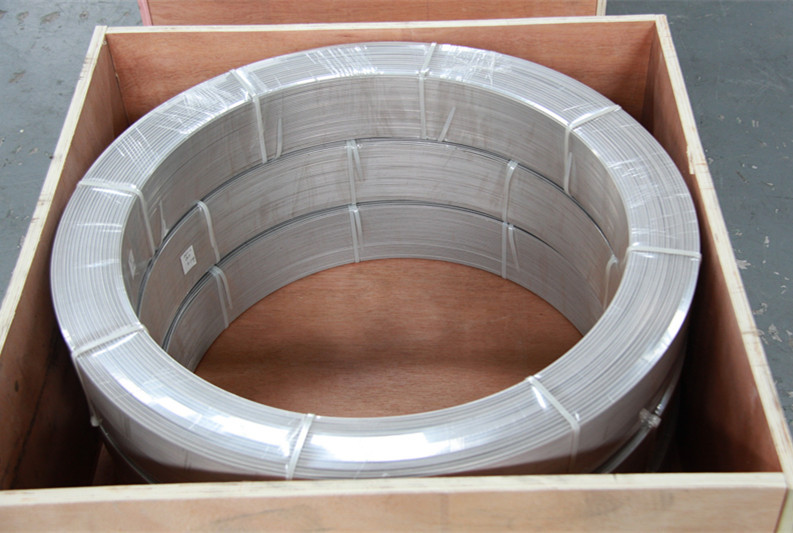

Good heat resistance titanium wire in coil for industry application

Detail Information

AS a titanium wire company supplier, we have been strictly inspected and the quality is guaranteed. Where to buy titanium wire is esay for you if you can contact us .will will try outr best to give you good services. The following are detailed information about our wires.

|

Grade |

Gr1, Gr2, Gr3, Gr4, Gr5,Gr7,Gr9,Gr12,Gr23 |

||

Standard | ASTMB348,ASTMB863,ASTM F67,ASTM F136 | ||

|

Diameter |

0.03mm - 5.0mm |

||

|

Technology |

Hot-Rolled, Cold-Rolled, Machining |

||

|

Surface |

Pickling surface, Polished surface, Black surface |

||

|

Specifications |

Aerospace, Medical, Industrial

|

||

Chemical composition

Grade | Chemical composition, weight percent (%) | ||||||||||||||

|

C ≤ |

O ≤ | N ≤ |

H ≤ |

Fe ≤ | Al | V |

Pd |

Ru | Ni | Mo | Other Elements Max. each | Other Elements Max. total | |||

Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 | ||

Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 | ||

|

Gr3 |

0.08 |

0.35 | 0.05 |

0.0015 |

0.30 | — | — |

— |

— | — | — | 0.1 | 0.4 | ||

|

Gr4 |

0.08 |

0.25 | 0.03 |

0.015 |

0.30 | — | — |

— |

— | — | — | 0.1 | 0.4 | ||

Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5~6.75 | 3.5~4.5 | — | — | — | — | 0.1 | 0.4 | ||

Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | 0.12~0.25 | — | — | — | 0.1 | 0.4 | ||

Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5~3.5 | 2.0~3.0 | — | — | — | — | 0.1 | 0.4 | ||

Gr12 | 0.08 | 0.30 | 0.03 | 0.015 | 0.30 | — | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 | |||||

Gr23 | 0.08 | 0.13 | 0.03 | 0.0125 | 0.25 | 5.5~6.5 | 3.5~4.5 | — | — | — | — | 0.1 | 0.4 | ||

Physical properties

Grade | Physical properties | ||||||

|

Tensile strength Min |

Yield strength (0.2%, offset) |

Elongation in 50mm Min (%) |

|||||

ksi | MPa | Min | Max | ||||

ksi | MPa | ksi | MPa | ||||

Gr1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

Gr2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

|

Gr3 |

65 |

450 | 55 |

380 |

80 | 550 | 18 |

|

Gr4 |

80 |

550 | 70 |

483 |

95 | 655 | 15 |

Gr5 | 130 | 895 | 120 | 828 | — | — | 10 |

Gr7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

Gr9 | 90 | 620 | 70 | 483 | — | — | 15 |

Gr12 | 70 | 483 | 50 | 340 | — | — | 18 |

Gr23 | 120 | 828 | 110 | 759 | — | — | 10 |

Tolerance (mm)

Diameter | 0.1~0.2 | 0.3~0.5 | 0.6~1.0 | 1.1~2.0 | 2.1~4.0 | 4.1~5.0 |

Tolerance | -0.025 | -0.04 | -0.06 | -0.08 | -0.1 | -0.14 |

Testing :

Chemical composition test,

Physical properties test,

Appearance defects inspection,

Eddy current testing.

Aerospace alloys and applications,

Medical implants,

Automotive applications,

Piercing & Accessory,

Optical frames,

Surgical instruments,

Architectural applications,

Cladding to other materials,

Bolts & Nuts,

Netting in corrosion。

Features :

High tensile strength;

High corrosion resistance;

Low density, good thermal stability;

Non-ferromagnetic;

Good bio-compatibility;

High temperature and low temperature resistance;

High resistance to strong acid and strong alkali and so on.

What we can do for you?

- If the above model is not suitable for your workpiece, please tell us your need and then we can send you the most satisfying drawing.

- contact us

Review

- Loading...

More than 10 year Foundry Operation Experience.

Committed to titanium processing and productionExported to +20 Overseas Countries.

- Mobile Phone

- *Title

- *Content

Titanium Custom Parts Manufacturing

NAVIGATION

More than 10 year Foundry Operation Experience.

Committed to titanium processing and productionExported to +20 Overseas Countries.

- Mobile Phone

- *Title

- *Content

Titanium Custom Parts Manufacturing

INFORMATION

- Tel:

+0086-917-3323952

+0086-15592563725

- WhatsApp:

- 8615592563725

- Skype:

- viresells2

- Address:

- Guojiacun Industry park,Maying Town,Weibin District,Baoji Shaanxi,P.R.China